Welcome back to the Fantastic Floor exclusive blog series,

Solid Flooring Installation. Last week we made sure your new

hardwood flooring was properly acclimated to the environment in which it will be installed. This week we’re digging deeper – literally – and discussing moisture testing.

We discussed moisture testing briefly earlier in the series as part of the acclimation process, but it is important enough to touch on again. Installers must know the moisture content of not only the flooring, but also the subfloor and the concrete slab below it, if there is one. Installation cannot occur if the moisture content isn’t just right. The following are basic tips for checking the moisture content of the sub-floor.

Remember: Hardwood flooring installation should be left to professionals or very experienced DIY-ers. If you have little to no experience with the process, call a professional.

1. Have the Right Equipment

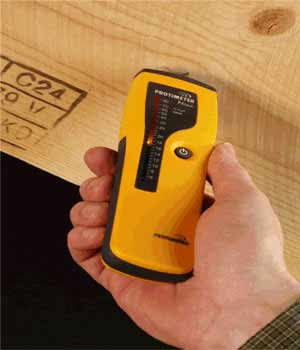

Having the right moisture meter is a very important part of moisture testing. Working with an improperly-calibrated meter, or not using one at all, is a very irresponsible flooring installation practice. The two main types of moisture meters are probe and pinless.

Probe meters are an older style of moisture testing, but they are still a fast and effective testing technique. These meters measure the electrical resistance across opposed sets of pins that have been pushed into the wood. The lower the resistance, the higher the moisture content.

Pinless meters, also called “non-destructive” meters, use electro-magnetic waves to measure the density of the area below the instrument. While many professionals prefer pinless meters because they don’t leave any pin holes, the machines do require a smooth surface and a flat measuring area.

2. Test the Right Area

Getting an accurate reading for the sub-floor moisture level means testing the right area and testing in the right intervals. As a general rule of thumb, test approximately 2 locations for every hundred feet and then take the mean average of all the readings. The acceptable moisture level for most areas of the country is 12% or less. Make note of any areas with unusually high moisture content – this could be a sign of some sort of leak or water damage.

3. Check the Concrete, Too

Testing moisture levels in wood sub-floors is relatively easy, but that is not the only part of the room that needs testing. Concrete slabs below the sub-floor can also cause problems if they don’t have the correct moisture content. Acceptable moisture content for concrete slabs during

solid hardwood flooring installation is 60% or less, or, less than 5.0 on a concrete moisture counter.

That’s it for this week’s installment of

Solid Flooring Installation. Tune in next week when we dive into the exciting world of vapor barriers. See you then!